1.Context & Product Scope

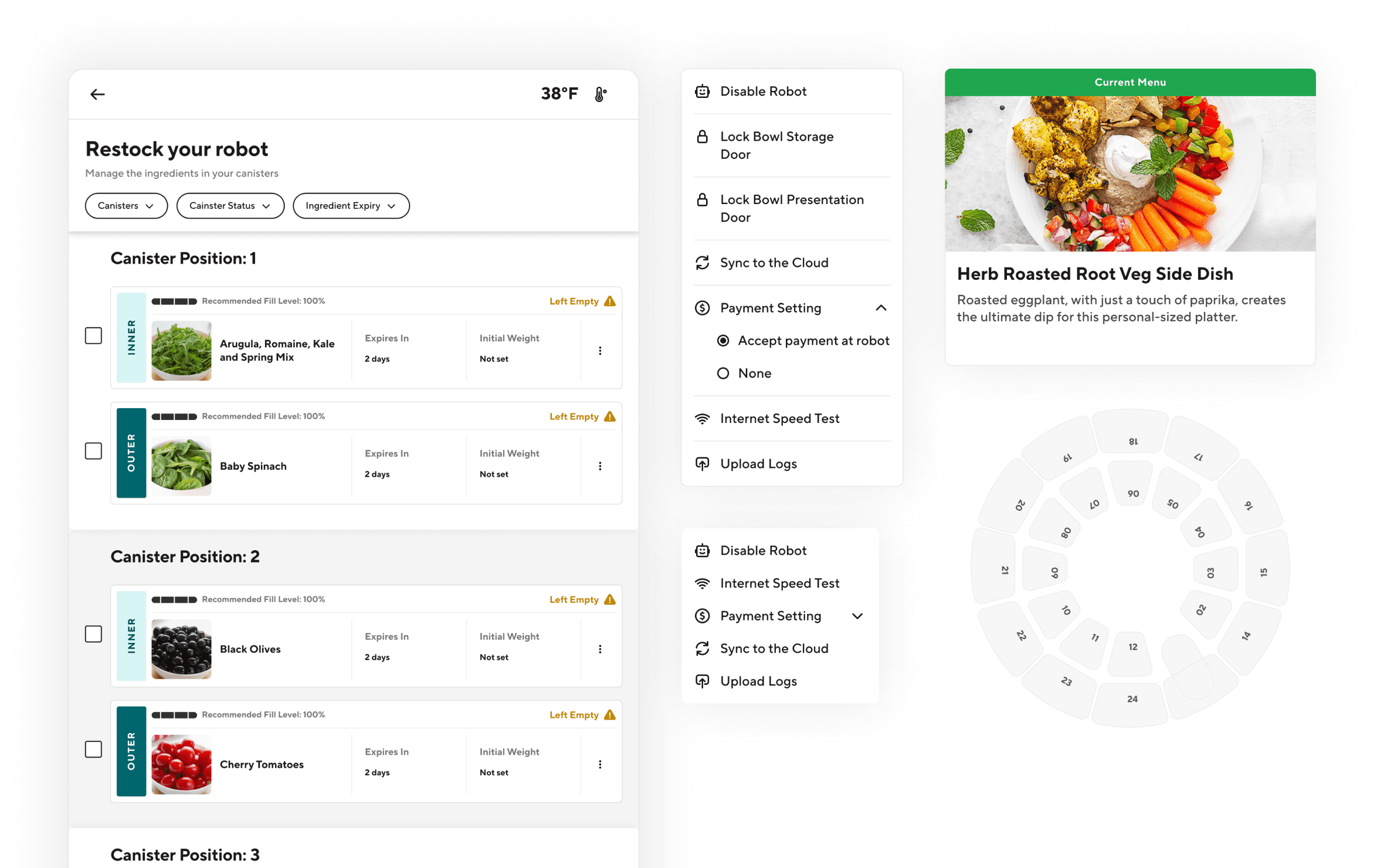

Sally is an autonomous food robot operating 24/7 across high-traffic environments (universities, hospitals, grocery stores), where operator efficiency directly impacts uptime, revenue, and customer trust.

2.Problem Framing

Robot downtime emerged as the primary system constraint, with restocking identified as the highest-leverage intervention point.

The existing restocking experience was step-heavy, cognitively demanding, and poorly instrumented, forcing operators to rely on memory rather than system guidance.

3.User & Domain Insights

Operator workflows spanned physical hardware + digital interfaces, creating friction at handoffs.

Key failure modes included:

Mental tracking of ingredients, quantities, and expiry constraints

Inefficient navigation between tablet UI and physical canisters

Lack of actionable visibility due to hardware sensing limitations

4.Design Strategy

Shifted restocking from a memory-driven task to a system-guided workflow.

Prioritized:

Step-by-step, glanceable UI

Reduced cognitive load and decision fatigue

Accessibility-first interaction models for diverse operator needs

Audio-visual feedback to bridge physical–digital gaps

5.System Constraints & Tradeoffs

Designed within hardware limitations (binary canister detection only).

Optimized for scalability and operational simplicity over visually complex but fragile interaction models.

6.Execution & Platform Thinking

Extended DoorDash’s Prism Design System for large robotic displays, ensuring:

Consistency with existing operator mental models

Faster adoption without retraining

A scalable foundation for future robot workflows

7.Outcome & Signal

Prototype testing with operators showed strong usability gains and clear reduction in perceived effort.

The redesign positioned restocking as a repeatable, low-friction system behavior, directly supporting reduced downtime and higher service availability.

8.Key Takeaway

The work demonstrates how systems thinking + domain depth + design execution can unlock outsized impact in human-robot operational products.